ON THE

MEASUREMENT OF THE JONDARYAN AND

SOMERTON BASE LINES

BY

CAPT. L. FITZGERALD. L.S.

O.C. GEODETIC SECTION, AUSTRALIAN SURVEY CORPS.

ARMY HEADQUARTERS,

MELBOURNE.

1939

C1015 Government Printer, Melbourne

REPORT

ON THE

MEASUREMENT OF THE JONDARYAN AND

SOMERTON BASE LINES

Part 1. - Introducing a Practical Method of Determining the Lengths of Steel Tapes in Terms of their Electrical Resistances.

Part 2. - The Measurement of a Base Line at Jondaryan, Queensland.

Part 3. - The Measurement of a Base Line at Somerton, New South Wales

BY

CAPT. L. FITZGERALD. L.S.

O.C. GEODETIC SECTION, AUSTRALIAN SURVEY CORPS.

ARMY HEADQUARTERS

MELBOURNE

1939

PART 1.

INTRODUCING A PRACTICAL METHOD OF DETERMINING THE TEMPERATURES AND LENGTHS OF STEEL TAPES IN TERMS OF THEIR ELECTRICAL RESISTANCES.

INTRODUCTION

To provide for adequate and proper control of its surveys, the Australian Survey Corps in recent years has included in its Establishment a Geodetic Section, the duty of which is to carry out 1st Order Triangulation, Base Line Measurement, Astronomical Observations, and all the requisite computations involved. This report is confined to a description of the methods used in the recent measurement of two base lines - one at Jondaryan, in Queensland, and the other at Somerton, in New South Wales. The report, it is hoped, will stimulate considerable interest in the Surveying Profession, as it describes a new departure in Base Line Measurement, which it is believed has not previously been successfully attempted in the field.

In Australia, Base Lines worthy of the name are very few in number, and mostly uncertain in dependability. The main ones are the Jondaryan (Queensland), measured in 1883, using steel tapes 100 ft. long, standardized against a steel bar 10 feet long; the Lake George Base (N.S.W.), 1870, and the Richmond Base (N.S.W.), 1879-80, using wood and steel bars 10 feet long, and more recently the Bourke Base, N.S.W., using invar bands. The Werribee Base, Victoria, was measured in 1860 with 10 feet bars. The Australian Survey Corps has been responsible for three base lines, one near Brisbane, Queensland, (1921); one at Millicent, South Australia,(1934), and one at Tarlee, South Australia (1934), using invar bands 5 chains long, standardized against the 66 feet Floor Standard of the New South Wales Lands Department.

Although satisfactory results appear to have been obtained, there has usually remained an element of doubt regarding the reliability of the reference standard used, and the Geodetic Section, before embarking on further base line measurements, decided to review its previous procedure. The Floor Standard mentioned above was the length between lines on copper plugs inserted in Trachyte blocks set in the basement of the Lands Department building, Sydney. The value of this standard was determined over 40 years ago. It is most likely that in the meantime its value has altered sufficiently to warrant its rejection as a reference standard for 1st Order base lines. As there is not yet established in Australia a Bureau of Standards or such body suitably equipped for the precise standardizing of survey tapes, it is necessary to send overseas, which means the National Physical Laboratory, for a suitable reference standard. This, under the circumstances, must be a Field Standard, and reasonably permanent in length, and implies a steel band.

The merits and defects of steel and invar bands have been so adequately discussed elsewhere, that a repetition here is not considered necessary. Suffice it to say that the main advantages of steel tapes lie in their permanency, and the fact that any damage causing a kink or bend is immediately noticeable. The big disadvantage is the difficulty of determining the temperature of the tape, which, an account of the relative high thermal co-efficient of expansion of steel, must be known exactly.

On the other hand, invar has a very small thermal co efficient, and the likely error in temperature determination can usually be tolerated. Inver, however, is subject to secular changes in length with time; it kinks very easily, and being more or less irregular, such a kink is likely to pass un-noticed. It is obviously not a suitable medium for a reference standard, but has been universally accepted as suitable for field measurements, provided that frequent comparison of length can be made against another more stable reference standard. This again meant that the reference standard must be a field standard, and being so, it could be taken for granted that a sheltered site would not always be available for it, and that exact determinations of temperature would be difficult. Tests on previous occasions by various authorities have shown that in sunshine the temperature of a steel band could quite easily be 6°F different from the temperature recorded by swing thermometers alongside the band. Suitable design of thermometers and special care in their emplacement would tend to overcome this deficit considerably, but even with all reasonable precautions, it is still likely that the thermometers might not register within 1° F of the true mean temperature of the tape. As the thermal co-efficient of steel is 6 x 10-6 per 1°F, an error of this amount could not be tolerated, and an improved and assured method of determining temperature was found necessary.

The method which was given serious consideration involved the determination of the tape temperature by measuring the electrical resistance of the tape. This idea followed upon an experiment carried out in 1935 at the University of Adelaide, S.A.

Just prior to that time, Major Vance and the writer had measured a base line at Millicent, S.A., and an investigation into certain differences between sections, pointed to a possible cause being an incorrect value of the thermal co-efficient of the invar as supplied by the makers. Professor Kerr Grant, Professor of Physics at the Adelaide University, was approached and asked to determine the co-efficient. He did so by first determining the temperature co-efficient of resistance of the tapes, and then raised the temperature of the tapes by passing through them varying currents from an accumulator battery and measuring the corresponding changes in length by means of a reading microscope. The success of the method was very encouraging, and it was decided to adapt it to the purpose of field standardization. The above test was made under laboratory conditions, and it was realized that field conditions would present difficulties which would have to be surmounted by careful attention to design and procedure. During the subsequent preliminary investigations, Professor Kerr Grant gave every assistance, advice and encouragement, and many aspects of a scientific nature raised in correspondence between Major Vance and Mr. Attwell of the N.P.L. were referred to him for an opinion. It is largely because of the soundness of his views and his decided opinion that the method could be successfully applied in the field, that the proposals were persisted in.

The first specifications for the equipment, on reaching the National Physical Laboratory (N.P.L.), started an exchange of correspondence between Major Vance and Mr. Attwell, in which many items of detail were finalized. Some of the more important points raised concerned the length of the bands. The first specification provided for 5 chain bands, as Inver bands of that length were already in the possession of this Section, but on the suggestion of N.P.L. these were amended to 50 metre lengths. This simplified the standardization and made for enhanced accuracy, and it seemed desirable in the first experiment with a new method to eliminate any unnecessary complications.

Another problem was to provide a suitable return lead for the electrical circuit. It was eventually decided to use a second tape (steel) for the return. By suitably adapting or redesigning the straining and measuring trestles, it was anticipated that the second tape could be used as a duplicate standard. How this was achieved is described later.

From the N.P.L. Certificates (Appendix "A"), it will be seen that the effect of a change of one ohm in the resistance of the circuit would affect the length of the bands (50 M.) by about .045 feet. As the standardization was to be of an accuracy of the order of 1/IM, it follows that the resistance of the bands should be measurable to within .003 ohms. This necessitated severe attention to the details of all connections. Mercury cups were at first considered. Such had been used in a previous experiment carried out by Mr. Attwell, and fully detailed in his paper "The determination of the Lengths of Steel Surveying Tapes in Terms of their Electrical Resistance", 1925. That experiment was carried out under laboratory conditions, and provided valuable experience from which to draw upon this occasion. The mercury cups were rejected as unnecessary and unsuitable for field conditions. Silver-gold-contact alloy for the tape terminals also presented difficulties, and eventually suitable brass plates were attached to the tape ends and were found satisfactory. The electrical leads were designed and supplied by N.P.L. These were of predetermined resistance, so that they could be embodied in the ratio arms of the Bridge.

The Bridge is a form of Kelvin Double Bridge capable of measuring resistances from 5 to 15 ohms to an accuracy of 0.001 ohms. Specifications were drawn up by N.P.L., which from this stage was mainly responsible for bringing the equipment to a state of finality. On receipt of the various items of apparatus from the tenderers, N.P.L. proceeded to carry out tests, and how well this was done may be seen from a study. of the appended copies of Certificates of Examination (Appendix "A"). The actual standardization was carried out as much as possible under conditions which could be repeated in Australia, e.g. the tension of 20 lbs. 10 ozs. was used as the weights already in use by this Section were of that mass. The Bridge, of course was the identical one sent out with the tapes and the leads were the same ones used in the Laboratory. The final results were given in the form of an equation expressing length in terms of resistance. This applied to the length of 50 metres between the calibration marks, and may be regarded as being accurate to within ±1 part in a million. On each tape was calibrated also a 66 feet interval. This was standardized in terms of temperature and the values may be regarded as accurate to within ±2 parts in a million. The 66 feet interval was intended mostly as a reference value for calibrating tapes other than those used normally for base line work, and for the purpose of this paper it has but little further significance.

An interesting point of some importance is the fact that the value of the rate of change of length with resistance (∂L / ∂R) was found to be different for each of the four tapes. For this reason, it was not possible to deduce the true length of an individual tape in terms of the combined resistance of a pair of tapes, but the mean length of the pair could be suitably expressed in terms of their combined resistance. This fact presented some difficulty in the design of the measuring heads used on the Field Standard Base, but a description of those fittings later on will show how that was overcome.

Photographs of the equipment are at Appendix “C”: -

Resistance bridge faceplate and in the field

Various items of special equipment

The bands and straining equipment THE FIELD STANDARD BASE. For the purpose of standardizing the Inver bands against the

Steel bands, it was necessary to construct a Field Standard Base, known

hereafter as F.S.B. The method and equipment used can best be followed by

reference to the appended photos and the plan of the Field Standard Straining

Gear. Two concrete posts were cast in position 50 metres apart.

Each post carried four studs to take a brass plate to which was fastened an

ebonite block, fitted as illustrated. On the centre portion of the ebonite

block a very fine scratch was made transversely to the line of the tapes when

in position. The ebonite block was cut away 1/50" so that the graduation

lines on the tapes would be co-planar with the scratched line and would abut

onto it. Ebonite studs were fitted for the purpose of holding the tapes in or

out of position. Actually, they were not required and were usually discarded. A

reading microscope was fitted into a supporting tripod and it was a simple

matter to bring the graduations of the tapes and the ebonite into sharp focus. A straining post of hardwood timber was set at each end

about one yard outside the measuring posts. One post was simply a holdfast for

the two tapes, which were fastened by lashing the straining cord through

another cord lashed around the post. These simple lashings proved quite

effective, and permitted fine adjustments to the alignment and elevation of the

tapes when under tension. The other post carried the straining pulleys.

Suitable pulleys were found difficult to obtain, and eventually two steel pressed

"scooter" wheels were fitted with bicycle ball bearing hubs, and the

tyre grooves filled and machined to a fine finish. The resulting job was very

well balanced and satisfactory. The spindles of the bicycle hubs were threaded

for a length of about 2 inches from each end, so that when the wheels were

bolted into position, a lateral movement of over one inch was possible by

adjusting the bearing cones. The two pulleys were bolted to steel straps which

in turn were held by bolts through the hardwood post. The drilled holes through

the post and the steel straps were sufficiently oversize to permit adjustments

of the pulleys in alignment, height and tilt. The studs holding down the

measuring heads also had sufficient latitude before being bolted down to allow

the heads to be rotated slightly, thus bringing the scratched line at right

angles to the line of the tapes. As the straining pulleys and marking heads

were left in situ for the duration of the base line measurement, the initial

fittings and adjustments were the only ones which took any appreciable time. As the tapes were to be used under the same conditions of

support as used by N.P.L., a boning rod was set midway between the measuring

heads. This consisted of a 2" x 2" hardwood pole driven in one inch off

line, and a 3" wood screw carrying a sleeve of glass tubing for insulation

purposes, was screwed in horizontally and transversely to the line of the tapes

and at the same level as the measuring heads. Sections of ordinary pencil

rubber were fixed over the glass tube to act as distance pieces between the two

steel tapes. Before describing the procedure of standardization, a few

remarks on the Inver bands should be in place. As previously mentioned, the invar bands used by this

Section were nominally 5 chains in length, ⅛ inches wide x .015 inches

thick. Two of these were now cut in halves and converted into four 50 metre

bands, nominally. Actually, they are 50 metres plus about 20 inches. On each

tape short scales were engraved at 0 and 50 metres corresponding to those engraved

on the steel tapes; each scale is 0.4 foot long and is sub-divided to 0.002

feet, the main sub-division lines being figured 0,1,2,………..20. The engraving of

the invar bands was very successfully performed by the Metrology Branch of the

Munitions Supply Board, Melbourne. A point of interest is the fact that the engraved lines on

the steel and invar bands are cut only half way across the width of the tapes,

which necessitates readings being made on one edge only of the tapes. This, no

doubt, is sound practice, but it affected the design of the measuring heads and

the procedure of standardization. Reference to the diagram will help that

procedure to be followed more clearly. As mentioned in the N.P.L. Certificates, it was necessary to

use the steel tapes in pairs, numbers 1 and 3, 2 and 4 being grouped for the

purpose. The diagram at Appendix “B” illustrates

Measurement No.31. E and W refer to the East and West ends of the Field

Standard Base, and steel tapes numbers 1 and 3 are in position. aa' and bb' represent the scratched line on the ebonite

blocks at the West and East ends respectively. It will be noted that the zero

graduation of No.1 tape is at the East end, and that of No.3 tape at the West

end. This permits the graduated edges to abut onto a, a', b and b'. If l1 = length of No.1 tape,

and e1 and w1 refer to the scale readings at the east and

west ends respectively, then ab = l1 - e1 + w1 . Similarly a1b1 = l3 + e3 - w3

and (ab + a1b1)/2 =

(l1 + l3)/2 = (e3 - w3 - e1 + w1)/2 . i.e., the mean length between the scratches aa1 and bb1 is

equal to the mean length of the two steel tapes plus the scale corrections as

shown. The mean length of the steel tapes is the value as provided by N.P.L. in

terms of the resistance, and as actually abstracted from the table at Appendix "E". From the copy of the page (Appendix “D”)

from the observation book, Measurement No.31 can be followed: – denotes the particular tape

observed. Column 2 gives the reading of the

bridge resistance at the instant of observations. Column 3 is the mean of two

resistance readings, one on each of the two tapes. Column 4 is the scale reading at the

E end in units of .02 feet. Column 5 is the scale reading at the

W end in units of .02 feet. The scales are actually graduated in .002 feet

intervals and estimated by eye to .0002 feet. The microscopes used permitted

this to be done with confidence. Column 6 is the difference between

the difference changes with the scale readings of (4) and (5): the sign of

the difference changes with the tape. Column 7 is the mean of the

difference of scale readings of tapes 1 and 3. Column 8 is (7) x .02 to reduce the

quantity to feet. Column 9 is the mean length of the

two tapes corresponding to Rm of column (3). The value is taken from the

table at Appendix "E". Column 10 is the algebraic sum of (8)

and (9), and is the value of the mean length between the reading scratches, i.e.,

it is the length of the Field Standard Base. Column 11 is the temperature as recorded

by thermometers. This temperature is not required, but it was usually taken

as a check on the resistance values, which could be converted into

temperature, of which more anon. Readings of end scales and the bridge were taken

simultaneously, observing in the order of tapes 1, 3, 3, 1, 1, 3. The interval

between observations usually occupied about ten seconds, so that the mean

differences can well be taken to coincide with the corresponding mean

resistance Rm. Three observations were made on each tape, giving three values

of the length of the F.S.B. as shown in Column (10). The mean of these three values

is the accepted length of the F.S.B. The range of the three values obtained in

Measurement No.31 is typical of those obtained in all such measurements. The results of Measurement No.36 are also shown. The usual

procedure was to determine the length of the F.S.B. first using steel tapes 1

and 3, then to compare the invar bands against the F.S.B., and finally to

determine again the length of the F.S.B., using steel tapes 2 and 4. The whole

process would usually occupy from one to two hours. By making entirely

independent measures with each pair of steel bands it could reasonably be

expected that any accidental error of consequence would be apparent in the results.

On no occasion did any such error appear. When two sets of measurements were

taken, the mean value was adopted for the length of the F.S.B. The copy of the observation page for Measurement No.32 (Appendix “F”) shows the method used for determining the

length of the 50 metre Inver bands: - Column 1 shows the time of

measurement Columns 2,3,4&5 give the air temperatures

as recorded by thermometers hung equidistant, close to, and at the same

height as the tape when under tension. Columns 6&7 give the scale readings

against the scratches at the E and W ends respectively. Column 8 is the difference between

(6) and (7) in units of .02 feet. Column 9 Is (8) x .02 to reduce the

interval to feet. Column 10 is for any relative remarks It will be noted that the sign of (8) is - E + W. The zero

graduation on the invar bands was placed at the West end. The procedure was to place the invar tape (No.4) in the

position previously occupied by No.3 steel tape with a covering remark in

Column (10), and under the same conditions of tension and support. Three scale

readings were then observed at each end with the microscopes; the thermometers

being read simultaneously. The invar tape was then shifted into position so

that the end of the scratches previously read against the scale of No.1 Steel

were underneath and close to the graduated edge of the invar. It should be

noted that the zero end stayed at the west end. The design of the microscope

and stand eliminated any likelihood of parallax errors coming in on account of

the tape being not exactly co-planar with the ebonite mark. The slight

difference in the separation of the tapes could be easily taken up on the

pulley spindles. Three more readings with corresponding temperatures were taken.

Mean values were abstracted as shown, giving a mean temperature and a mean

scale correction. To the mean temperature was applied a calibration correction,

obtained from the temperature calibration sheet as appended. A standard

temperature of 70°F was adopted for the invar bands and the correction to

standard temperature was a simple matter. The co-efficient of thermal expansion

of the invar had been determined by Professor Kerr Grant, prior to cutting the

5 chain tapes, and his mean value of 1 x 10-6 per 1° C. was adopted

for the 50 metre lengths. A simple algebraic sum of the length of the F.S.B.,

the mean scale correction, and the correction to standard temperature, gave the

length of the invar band at 70° F or the chord distance under a tension of 20

lbs. 10 ozs., and with one central support, as such were the conditions of

standardization by N.P.L. THERMOMETERS. The problem of obtaining true tape temperatures by means of

thermometers has been very well treated in two papers embodied in the Report of

Proceedings of the Conference of Empire Survey Officers, 1935 : "Effect of Temperature on Field Measures", by

J. Glendinning, Surveyor-General, Gold Coast Colony. "Temperature Correction to Steel Tapes", by

G.K. Thornhill, Surveyor-General, Ceylon. Four thermometers, graduated into single degrees Fahrenheit,

and estimated to tenths, were used on the Jondaryan and Somerton base lines.

They were calibrated by comparison with a Standard Thermometer, graduated to

fifths of a degree F. A range between 46°F and 108°F was obtained by immersion

in a tank of water. The temperature was raised by the addition of hot water,

then allowed to cool off again. The differences at various points were plotted

on a graph, and a correction curve drawn for each thermometer. The appended

Calibration Chart (Appendix "G"), was compiled

from the curves. Two of the thermometers were enclosed in invar casings as

shown in the photo. The casings were constructed from strips of invar band ¼

inch wide. It was hoped that such casing would respond to atmospheric changes

as the tape would, and that the enclosed thermometers would register reliable

temperatures. The thermometers were suspended parallel and close to, but not

touching, the tape, and with the bulb slightly lower than the other end. At Jondaryan, the F.S.B. was established in a sheltered and

shaded place, under a row of pepper trees, and for a considerable time of the

day there were complete shade and calm and the conditions for observations were

very good. Because of this, only the two cased thermometers were used, and they

appear to have been sufficient. For the Somerton base line, the F.S.B. was established out

in the open, unshaded and mostly unsheltered. This was done partly of necessity

end partly to permit the Resistance observations to be examined under less

favourable conditions than at Jondaryan. Close to the western end of the Somerton F.S.B. a tent was

erected for housing the measuring equipment, and to allow the Bridge to be kept

in the shade during observations, the leads being long enough for that purpose.

It was noticed that this tent had a sheltering effect on any westerly breeze which

might be blowing. As the air temperature was about 80°F, this breeze usually

had a cooling effect, and the air temperature at the west end usually recorded

higher than elsewhere along the tape. Four thermometers were placed equidistant

along the tape and observed simultaneously with Bridge readings. (See

temperature comparisons - Measurement 31.) Thermometers a and d were the cased

ones, and b and c were uncased. It appears that the casing has the effect of

raising the temperature about 3°F, which is what was expected. From the

temperatures deduced from the resistance values, it would seem that the cased

thermometers read too high and the uncased ones too low, but as this particular

measurement was subject to breeze and uneven shelter, the observations are not

conclusive. Under more stable conditions such as existed at Jondaryan, similar

comparisons showed that the mean of the two cased thermometers agreed closely

with the temperatures based on the resistances. Further extensive observations will be made for the purpose

of determining the behaviour of thermometers under various conditions of

suspension and casing. Before leaving the subject of the Field Standard Base, a few

remarks on the results obtained should be in place. Each terminal of the Field

Standard Base at Jondaryan consisted essentially of a precast hollow concrete

pipe, in the form of a frustrum of a cone, 18 inches diameter at bottom, 9

inches diameter at top and 4 feet high. (These are normally used for

triangulation pillars.) This was set and rammed into a hole 2 feet deep,

leaving 2 feet above ground. The inside was filled and rammed with soil and

gravel, with a depth of about 9 inches of concrete at the top, into which was

set the four studs to take the brass and ebonite reading block. The stability

of the terminals can be gauged from the values of the length of the F.S.B. as

shown here. Measurement No. Length of F.S.B. (feet) 1 164 .03784 4 .03801 5 .03710 7 .03726 10 .03733 13 .03747 18 .03722 19 .03757 24 .03709 Heavy rain set in after Measurement No.4, and apparently

caused a slight settling of the terminals. Thereafter, the values show

stability and gave every confidence, and it is safe to assume that no shift would

take place during actual times of measurements. At Somerton the lengths of the

F.S.B. were not so consistent, but as horses were noticed on several occasions

to be using the terminals as "itching” posts, therein lies the reason. The lengths of the Inver bands as determined by comparison

with the steel standards, are given in Appendix

"H", It will be seen that every tape kept its length very well, and

as the practice was to use each tape for only one day's chainage before

re-standardizing, there was little likelihood of any accumulation of errors

caused by change in the length of the tapes. This view is well supported by an

investigation of the field measures. Before concluding this section of the report, the writer

would like to stress the fact that the procedure just described is actually a

simple one. The preliminary investigations by N.P.L. and the design of the

measuring appliances certainly took much time and trouble, but they have been

well justified by the consistency and reliability of the results. The

electrical connections presented no abnormal difficulties. Every item of the

measuring gear functioned perfectly and on no occasion was an observation made

which gave an unaccountable or intolerable result. PART 2. THE MEASUREMENT OP A BASE LINE AT JONDARYAN, QUEENSLAND. This base line is just over 7 miles long, and is situated on

open plain country, about 10 miles south of the township of Jondaryan,

Queensland. The East and West terminals are on Mounts Irving and Maria

respectively, the height of the former being 216 feet and the latter 162 feet

above the level of the plain. This base line was first measured by the Queensland State

Lands Department, in 1883-4. Steel tapes 100 feet in length standardized

against a steel bar 10 feet long were used. The Australian Survey Corps decided

to remeasure the base with 50 metre Inver bands. The equipment used consisted

essentially of: - 4 Invar bands 50 metres long, ⅛"

wide, and .015 inches thick, graduated as described in the

preceding report. 4 Measuring trestles fitted with

special reading heads. 2 Straining trestles. 2 Weights of 20 lbs. 10 ozs. each

for applying the tension. 2 Thermometers, cased in Inver. 2 Reading glasses. 1 Boning rod with sliding vane. 1 Cook, Troughton & Simms,

Geodetic Tavistock Theodolite. 1 Watts 3" Theodolite. Box tapes, plummets, cords,

swivel hooks, etc. Special reading heads were designed by the writer and made

in the Ordnance Workshops, Melbourne. The details can be seen from the

photographs. They were so designed that they could be attached to existing

types of theodolite tripods - an economic as well as a convenient factor. The

main plates provided for a traversing movement, and the universal ball joint

gave adjustments in azimuth and tilt. When in use, the Inver tape was supported

on the cut away edge, and the graduated marks read against a fine line scratched

in the silver plate. These measuring heads proved very successful. They were

easy to set, and the clamping devices gave ample security. The straining trestles provided movements in elevation and

azimuth. Adjustments for tilt and lateral shift had to be made by means of the

trestle legs. This was not very satisfactory, and orders have now been placed

for two straining trestles of an approved type. A 20 pound weight was hung to each

of the straining trestles to make them more stable. The thermometers have been described previously, and no

special comment need be made concerning the weights, boning rod, or reading

glasses. The straining cords were the same as used during standardisation

against the F.S.B., and were fitted with suitable swivel hooks. The base line was pegged out at 50 metre intervals,

commencing from the Maria and, and the R.L. of each peg was found with a dumpy

level. The pegs were of 2" x 2" hardwood, and every tenth bay was

defined by a brass plug set in a concrete post, 3 feet long, precast and buried

with the plug usually at surface level. These brass plugs were marked with a

centre punch and transverse scratches. Their positions were picked up during

the chaining by setting the measuring head mark exactly over them. This was

done by means of the theodolite set about 10 feet square off the line of the

base. The base was measured twice and these permanent references gave

comparisons of the lengths of every ten bays. (see later.) It was considered that the terminal slopes might be excessive

for precise chaining, and skew bays were laid out and measured as illustrated.

At the Maria end, both the straight and skew sections were measured. The

straight section gave a maximum slope of 15 degrees, and this was the limit of

rest of the tapes. On a steeper slope, the added downward pull would have

caused the tapes to roll off the pulleys. The Irving end was considerably

steeper and no attempt was made to measure on the straight line. The three

angles of the triangle formed by the straight and skew sections were read with

a 5½" Cook, Troughton & Simms, Geodetic Theodolite, and the straight

section computed therefrom. At the Maria end, the difference between the

computed and measured lengths was .01114 feet. It is considered that the computed

value of the Irving Section would be correct within the same. limit. As this

difference is not cumulative, it can be tolerated. The actual procedure during measurement was quite a normal

one. Four reading trestles were used. This permitted a rear one to be left

undisturbed until the "all clear" signal was given. The fourth

trestle was set one bay in advance and proved a considerable time saver. The speed of the measurement should be of interest. The writer

was the only one amongst the party who had had previous experience in base line

measurements, although the other members of course, understood the procedure.

The first few bays took about 20 minutes each to observe, on account of the

strangeness of the duties. A goal of 10 minutes was set by the O.C. as a

reasonable time. Careful attention to details and system soon showed a marked

improvement and eventually the time of measuring a bay became as low as 5

minutes, and the usual time per section of 10 bays, about one hour. When adapting the old 5 chain tapes to 50 metre ones, it was

expected that the speed of measurement would be less on account of doubling the

number of bays. This expectation was soon shattered, and 70 bays, or 2.17 miles

per day of about 9 hours, were measured on three occasions, compared with a

maximum of 2 miles on a day of 10 hours previously measured with a 5 chain

band. Weather conditions were certainly favourable. The progress of the

measurement can be followed from an inspection of the appended

"Chronological Order of Measurements" (Appendix "J", Jondaryan and Somerton). It will be

seen that the 2nd measurement, except for 5 bays, was completed in 4

consecutive days, including the standardizing of the tapes. Speed was not

considered of primary importance, but every advantage was taken of suitable conditions,

and the very satisfactory progress is attributed to the keenness and whole-hearted

co-operation of every member of the measuring party. The personnel and their main duties were as follows: - Capt. L. FitzGerald, L.S., O.C.

Geodetic Section General direction of the

work, and observer of electrical resistance measurements. Lieuts. A.F. Kurrle, L.S.,

and H.A. Johnson, L.S., Survey Officers, Geodetic Section Observers at the tape ends

on both the Standardizing and Field Measurements. Warrant Officers J. Hanley

and G. Steele Recorders and observers of

the temperature readings. Corporals Nolan, Meehan and

Breen Attending to the boning

rod, application of the tension, and bringing forward the reading trestles,

on completion of a bay. Three Survey Hands One usually assisted with

the gear, the other two attended to transport and camp duties. Warrant Officer A. Townshend,

L.S., joined the Section after

completion of the Jondaryan base line, and assisted with all duties on the

Somerton measurements. The reduction of the measurements was made by Capt.

Fitzgerald and Lieuts. Johnson and Kurrle. REDUCTION OF THE OBSERVATIONS. A sample page from the field book is attached (Appendix "K"). Column 1 gives the number of the bays

being measured. Column 2&3 for the temperatures

recorded on the cased thermometers, and adjusted for calibration error. Column 4 mean temperature. Column 5&6 the scale readings in units

of .02 feet. Column 7 the scale difference. It

will be seen that three readings are taken on each bay, the tape being moved

slightly for each one. Column 8 the mean of the three

differences shown in (7). Column 9 R.L. of the bay peg. Column 10 height of the measuring

head above the bay peg. This height was measured independently by each

observer, using a box tape. Column 11 (9) + (10) and gives the

R.L. of the measuring head. Column 12 the difference in R.L. of

successive measuring heads, from which the slopes are deduced. Column 13 any relative remarks. Column 14 summation of the values in

column (6) multiplied by .02 to reduce to feet. Column 15 slope correction for each

bay. When the difference in R.L. between the two ends of a bay does not

exceed 5 feet, the correction is taken direct from tables prepared for that

purpose. When the difference is over 5 feet, the correction is taken out

independently, applying the scale correction to the length of the tape, so

that the true slope is obtained. Slopes over 6° were checked

by observations with the theodolite. Column 16 correction to the standard temperature

of 70° F. It is based on a mean temperature over the usual ten bays which

comprise a section. Column 17 correction to the standard

length of the tape being used. (See Appendix

"H"). Column 18 any other correction which

may be necessary, e.g., deformation of the catenary, or sag on an odd length

of tape. Column 19 summation of (14) to (18)

inclusive, and represents the total correction to be applied to n x 164 feet,

i.e., on the section illustrated the total length of the section is 1640 + .24342

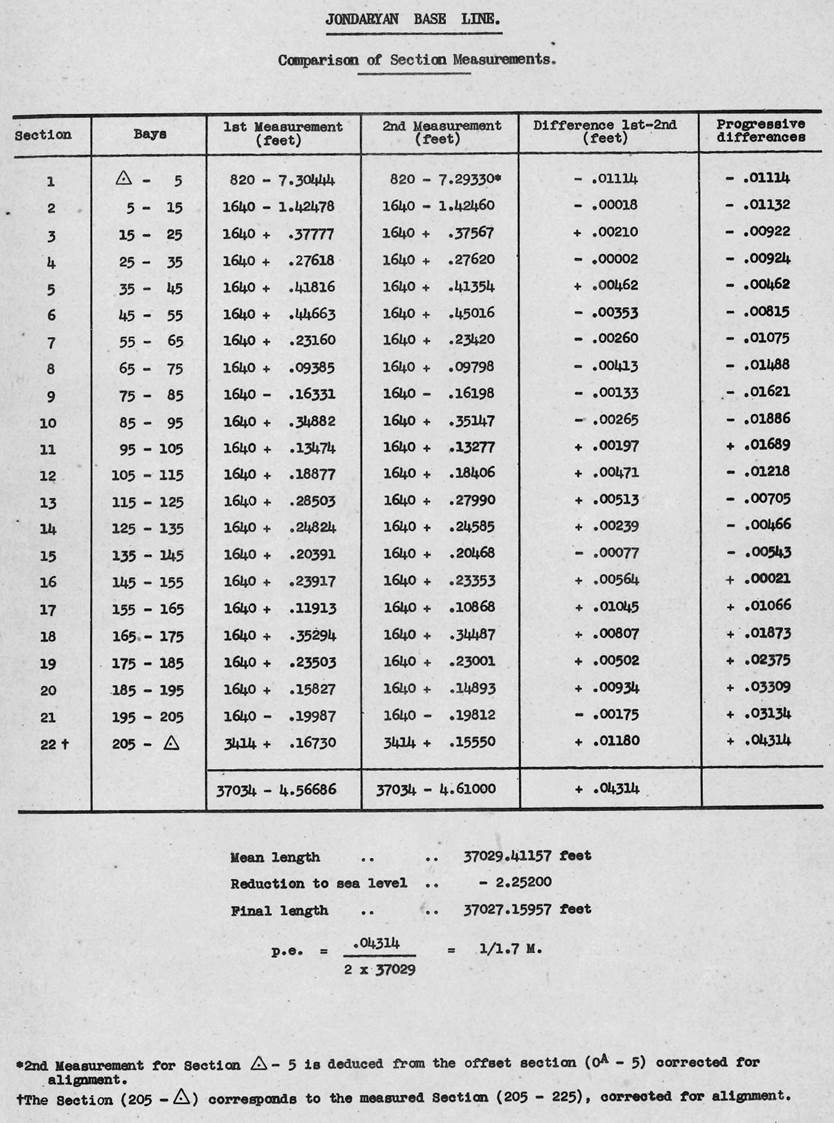

feet. From the Comparison of Section Measurements, it will be seen

that the total difference between the two measurements is .04314 feet. Most of

this occurs in Sections 17 to 22. During the second chainage of this portion,

there was a west wind blowing along the tape. Had this wind been across the

tape, the measurements would have been suspended, but as a close check on the

observations at the time did not disclose any obvious inconsistencies, the work

continued. These measures gave shorter values for the sections. A cross wind

would have the effect of shortening the tape, resulting in section lengths

being too long. It seems to the writer that a wind blowing along a suspended

tape would have a lifting effect on the catenary curve, with consequent flattening,

increase in tape length, and shortening in the length of the sections. This

theory is supported by the results obtained. Section 21 was measured in

comparative calm, and this can account for the reversal of sign. The final length reduced to sea level is 0.3433 feet shorter

than the value previously obtained by the Queensland State Lends Department in

1883-4. This supports a statement by that body that the value ascribed to the

Queensland bar in 1883 was too high. (See "Report of Conference of Surveyors-General

- 1912"). The original terminal mark on Mount Irving was found

damaged, but was re-established with a reasonable certainty of being not more

than 1/20 inch out of position. Four of the original section pegs were located

and tied in to the chainage. These were of concrete, but unfortunately, they protruded

shout nine inches above the surface, and had obviously been disturbed. The fact

that the other old section blocks were missing, points to the unreliability of

those blocks as permanent references. Actually, a comparison between the old

values and the new give discrepancies of about two inches between sections,

with a maximum progressive difference of six inches. This is attributed to the

instability of the original section blocks. The terminal mark on Mount Maria

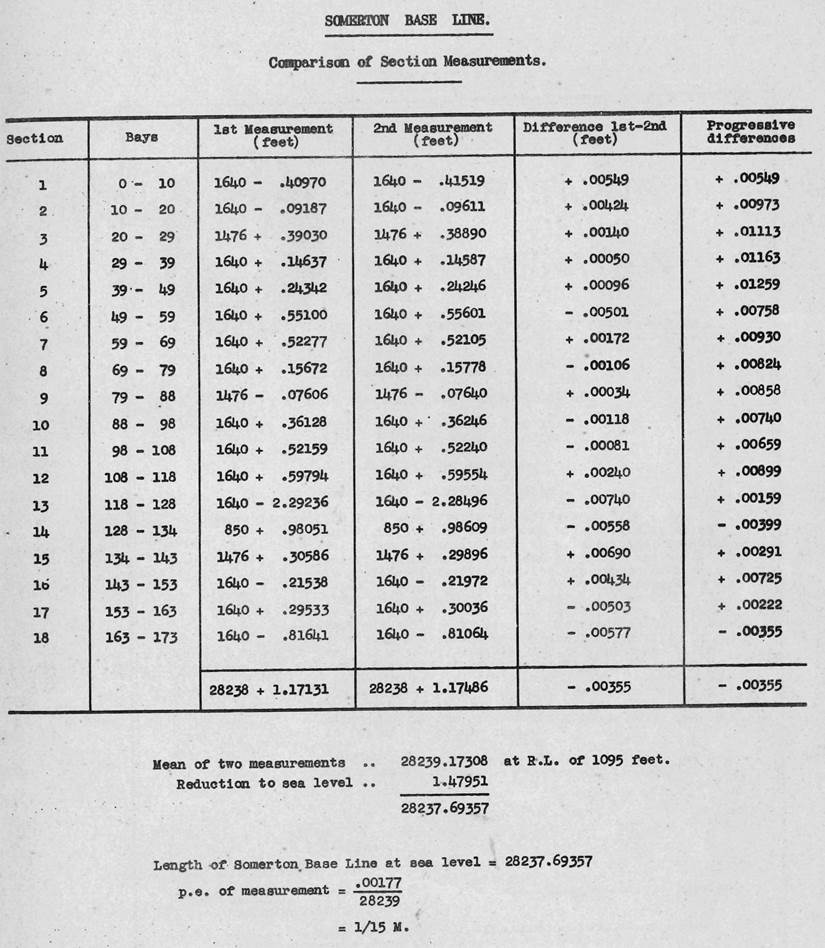

was found to be in good order. PART 3. THE MEASUREMENT OF A BASE LINE AT SOMERTON. NEW SOUTH WALES. The Somerton Base Line is 5.35 miles long, and situated 5

miles North West of the Township of Somerton, in the County of Darling, N.S.W.

From the. North Base, the line slopes steadily downwards the Peel River, then

gradually upwards to the South Base Terminal, near the main Tamworth-Gunnedah

road. This site was selected by the writer. The extension from the

base net connects with the northern limit of the N.S.W. State Triangulation,

and provides a check thereon. A new chain of 1st Order triangulation carried

out by the Australian Survey Corps extends from the base line northerly to the

Queensland border near Wallangarra. The procedure and the equipment used were the same as

adopted for the measurement of the Jondaryan Base Line. The section pegs of

concrete were poured in situ, and the brass plugs set in position. The North

and South Base Terminals are defined by brass cartridges finely centred, and set

in brass tubes, embedded in concrete blocks poured in situ. These marks are

just below the surface. Over each ground mark was set a concrete pipe 4 feet

high, filled with concrete and having a standard bronze plaque with centre

brass plug set in the top. The centre of the top plug was set exactly over the

ground plug, from which the base line measurements were actually made. Usually

the sections consisted of ten bays. A preliminary chainage indicated that the

odd length of base not covered by full 50 metre lengths amounted to about 29

feet. As the crossing of the Peel River would necessitate a change from even 50

metre bays, it was decided to measure all the odd lengths on the river section.

This was done by interposing two sections of 98 feet (50 metres - 66 feet), and

by taking up the small residual on the measuring heads, which give a latitude

of 4.8 inches. The maximum elope was 6° 15', and conditions for measurement

were very favourable. The line was measured twice and the comparison of Section

Measurements indicates a marked consistency, and freedom from any accumulation

of errors. The actual measurement of the first bay commenced an

7/9/1939 and the last measurement was made on 19/9/1939.